FIRE EXTINGUISHERS

Do You Have The Right Protection?

Our world is full of potential hazards and nothing matters more to Fox Fire than knowing our customers have the right 1st line of defense. We proudly sell Ansul, Badger, and Amerex fire extinguishers in all sizes and will install them to ensure your business meets or exceeds NFPA and local fire code requirements. Every new extinguisher purchase comes with the 1st year inspection, a mounting bracket, and a complimentary scheduling service to make sure your tags never expire.

Maintenance Compliance

Extinguishers need to have maintenance on a regular schedule to ensure they work when needed the most. Our technicians are specially trained to recognize when maintenance is due and when repairs need to be made. Fox Fire also happens to be one of the few DOT certified requalification facilities in Northern Indiana to help keep your costs to a minimum.

Maintenance Schedule

1 Year - Annual Inspection

5 Year - Hydrostatic Testing for CO2, H2O, & other wet chemicals

6 Year - Functional Testing for Stored Pressure, Halogenated

12 Year - Hydrostatic Testing for Stored Pressure, Cartridge Ops, Halogenated

Inspection Expectations:

1: New Tag / Safety Tamper Seal

2: Verify Extinguisher Location

3: Assess Visibility and Signage Functions

4: Ensure Total Access to Extinguisher

5: Verify Gauge Reading is in Operable Range

6: Check Fullness by Weight

7: Verify Pull Pin Functions Properly by Removing

8: Check / Record Maintenance Dates

*Additional inspection procedures may be required on some units.

**Inspectors & Inspections are regulated and follow NFPA 10: Chapter 7 fire standards.

KITCHEN SYSTEMS

In the heat of the moment, your in-hood kitchen fire suppression system could easily make the difference between a close call and a total loss. You don’t want to get caught behind the curve on inspections or maintenance when a fire starts. Fox Fire employees are all extensively trained & certified through the appropriate manufacturers to inspect, service, or install any kitchen fire suppression system. Our company holds a diamond Ansul distributorship and is a one stop source for designing and engineering a custom system for your kitchen. Check in with us if you are interested in or have recently remodeled your kitchen. Specific appliances are protected by different nozzle spray patterns that need to be moved along with your appliances to ensure the correct coverage.

Maintenance Schedule

6 Month - Semi-Annual Inspection, Fusible Link Change

12 Year - Hydrotesting for Stored Pressure Tanks

Inspection Expectations:

1: New Inspection Tag / Safety Tamper Seals

2: Manual Pull Stations are Unobstructed

3: Tamper Indicators / Seals are Intact

4: No Physical Damage or Obstructions hindering operation

5: Gauges are inspected physically or electronically to ensure it is in the operable range.

6: Nozzle caps are intact & undamaged

7: Appliance lineup / hazards haven’t been moved or replaced

8: Check / Record Maintenance Dates

*Inspectors & Inspections are regulated and follow NFPA 17:17A fire standards.

INDUSTRIAL SYSTEMS

A dry chemical fire suppression system is an easy and cost-effective way to protect a variety of special hazards you will find in an industrial environment. They offer full time protection for high risk areas via both automatic and manual actuation. Fox Fire Safety is highly specialized and an industry leader for the installation and maintenance of dry chemical systems. We work together with RV manufacturers, furniture fabricators, auto body shops, and many others to engineer systems specific to their needs. Industrial dry chemical systems are great for protecting:

With local application for individual machines or total flooding for enclosed spaces, Fox Fire is confident our team will be able to work with you to fully protect your assets, from installation to routine maintenance and service calls.

Maintenance Schedule

6 Month - Semi-Annual Inspection, Fusible Link Change

6 Year - Functional Maintenance for Stored Pressure Tanks

12 Year - Hydrotesting for Stored Pressure Tanks

Helpful Links

**All systems are subject to the NFPA mandated 6-month inspection, but testing and maintenance requirements differ. Please call a Fox Fire Safety representative today for the specifics. All inspectors and inspections are regulated and follow the appropriate NFPA fire standards.

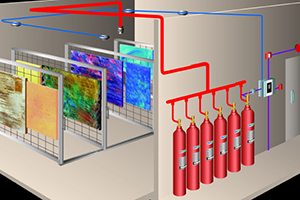

SPECIAL HAZARDS

Not all hazards are the same, but all fires do one thing – destroy. So, what do you when you have those special hazards requiring a different level of protection? Call the team at Fox Fire Safety. We can assess the situation and design a system specific to your needs, whether it calls for Clean Agent, Water, AFFF Foam, or Carbon Dioxide. We are knowledgeable and fully equipped to streamline the installation, inspection, or service process and keep you fully informed about your system and it’s needed maintenance. Check out the different system lines below:

Clean Agent:

When you want protection for valuable assets or expensive equipment, Fox Fire turns to Clean Agent suppression systems. These systems are customizable to virtually any space, big or small, and provide a faster, more effective version of protection. The gas is safe, non-toxic, and requires zero effort for clean-up. It’s also harmless to sensitive electrical equipment and the preferred protection method for companies with server rooms and important computer driven machines.

Carbon Dioxide:

Carbon Dioxide suppression systems are perfect for protecting a single machine or multiple machines in a manufacturing setting. They provide early detection, quick action, and are more cost effective than a dry powder system. Zero cleanup! There are high and low-pressure options available depending on the hazards present.

AFFF Foam:

AFFF Foam or Water Mist systems are great for high hazard facilities with flammable liquids like gas and oil. They utilize heat or smoke detection and are also very flexible when it comes to customization. These systems are most commonly found protecting aviation hangars, power plants, tanks farms, and chemical facilities.

**All systems are subject to the NFPA mandated 6-month inspection, but testing and maintenance requirements differ. Please call a Fox Fire Safety representative today for the appropriate maintenance schedules. All inspectors and inspections are regulated and follow the appropriate NFPA fire standards.

SPRINKLERS

When a fire strikes, it can go undetected until it’s too late. An automatic wet or dry sprinkler provides instantaneous protection for you, your employees, and your business. Sprinkler systems need to conform to NFPA 25 standards in order to be compliant, as well as local fire codes, local building codes, and insurance requirements too. A properly maintained and continuously inspection sprinkler can also bring about possible benefits in the form of reduced insurance premiums and the potential for reduced fire damages in the future. Fox Fire Safety has the resources to offer a complete service package when it comes to sprinkler inspections, repairs, testing, monitoring, and installation – including additional components like hydrants, backflows, fire pumps, hoses and hose standpipes. Give us a call today so we can get you started.

**All inspectors and inspections are regulated and follow NFPA 25. Please call a Fox Fire Safety representative to discuss the testing and maintenance schedule for your sprinkler.

ALARMS

Fire alarms are an instant signaling system that save lives and as such, they need to be inspected frequently and properly maintained. Fox Fire Safety understands how important they truly are and has the resources to have all brands of alarms inspected, tested, monitored, and serviced. We know a few seconds could make the difference during a crisis and want to make sure those precious seconds are available when needed the most. Give us a call today and a certified team can go over what to expect during an inspection or the specific testing schedule mandated by NFPA and local fire codes. Reports detailing the location of all manual actuation and signaling devices will be available after each inspection along with a deficiency report so you are kept informed about your fire alarm.

**All inspectors and inspections are regulated and follow NFPA 72. Please call a Fox Fire Safety representative to discuss the testing and maintenance schedule for your sprinkler.

ADDITIONAL PRODUCTS

Fire Hoses:

Fox Fire sells and services fire hoses in accordance with NFPA 1961 – including pressure re-qualification! Curious if adding hoses would be a smart move to protect your facility or if your existing ones should be removed? Our knowledgeable technicians can analyze your potential hazards and recommend the best course of action.

Safety Lights:

When the lights go out, your safety lights should be there to show you the way. A power outage or emergency isn’t the time to find out they don’t work. The lights are required to have 30-second and 90-minute testing each year and are regulated by NFPA 101 and OSHA safety codes. Fox Fire carries a full line of new exit, emergency, and combo lights in addition to a wide variety of batteries and bulbs to keep your lights shining bright.

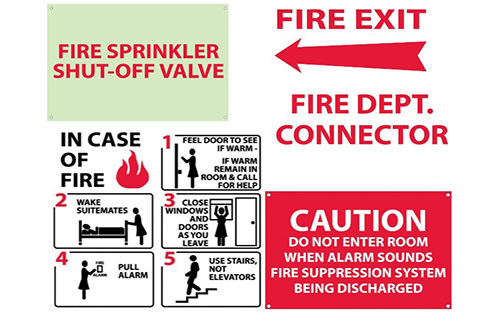

Customized Signs:

Needs signs? Fox Fire can have them made in any size, shape, or material you may need. They are available with durable foam adhesive or pre-drilled holes for your convenience. Step up your safety game and order today!

Quotes are available upon request.